Collaboration

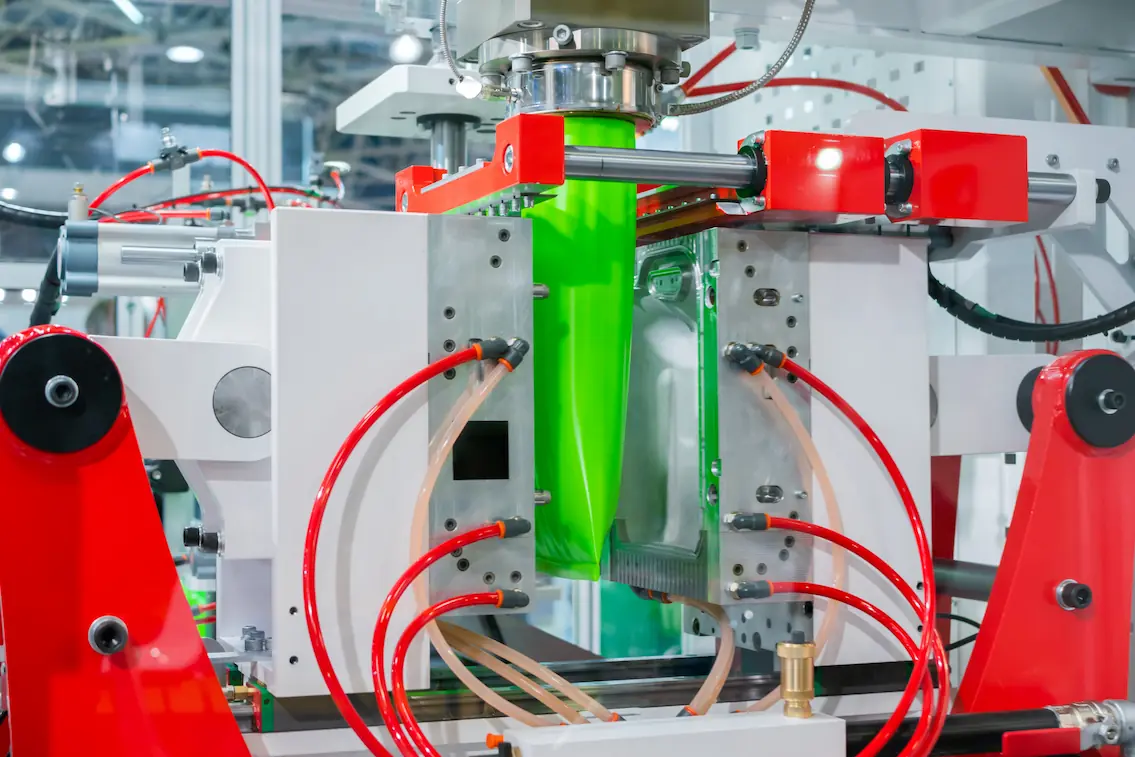

Innovative Air Duct for Schmitz CargobullAt Pentas, we take pride in serving a wide range of industries, including the automotive sector. In this industry, the use of rotational moulding is increasing due to the unique advantages the technique offers. One example is our collaboration with Schmitz Cargobull, a leading player in the transport sector specializing in trailer manufacturing. Together, we developed a sustainable solution to replace traditional sheet metal air ducts with robust and flexible air ducts produced through rotational moulding. In this case study, we take you through the challenges, the process, the collaboration, and the results of this successful project.