CLAAS

Lighter tank saves fuelThanks to our sophisticated wall thickness design, the new fuel tanks are 25% lighter with identical stability. This allows CLAAS to improve their fuel efficiency without compromising on safety.

We manufacture custom plastic products, exactly the way you envision it. And more lightweight, stronger and more sustainable if possible. Because we perfect the technique of mould construction and rotational moulding every day.

About Pentas

The possibilities of plastic rotational moulding are endless. From fuel tanks for agricultural machines and slosh dampers for windmills to toilet cabins… The more challenging the better. It takes a lot of technical knowledge and boldness to realise the right future-proof solutions. And we have everything it takes to do just that.

Rotomoulding

CLAAS

Lighter tank saves fuelThanks to our sophisticated wall thickness design, the new fuel tanks are 25% lighter with identical stability. This allows CLAAS to improve their fuel efficiency without compromising on safety.

Working method

Clients appreciate in-house mould constructionIn a nutshell, agility and confidential information security are the benefits of in-house mould construction.

Pentas

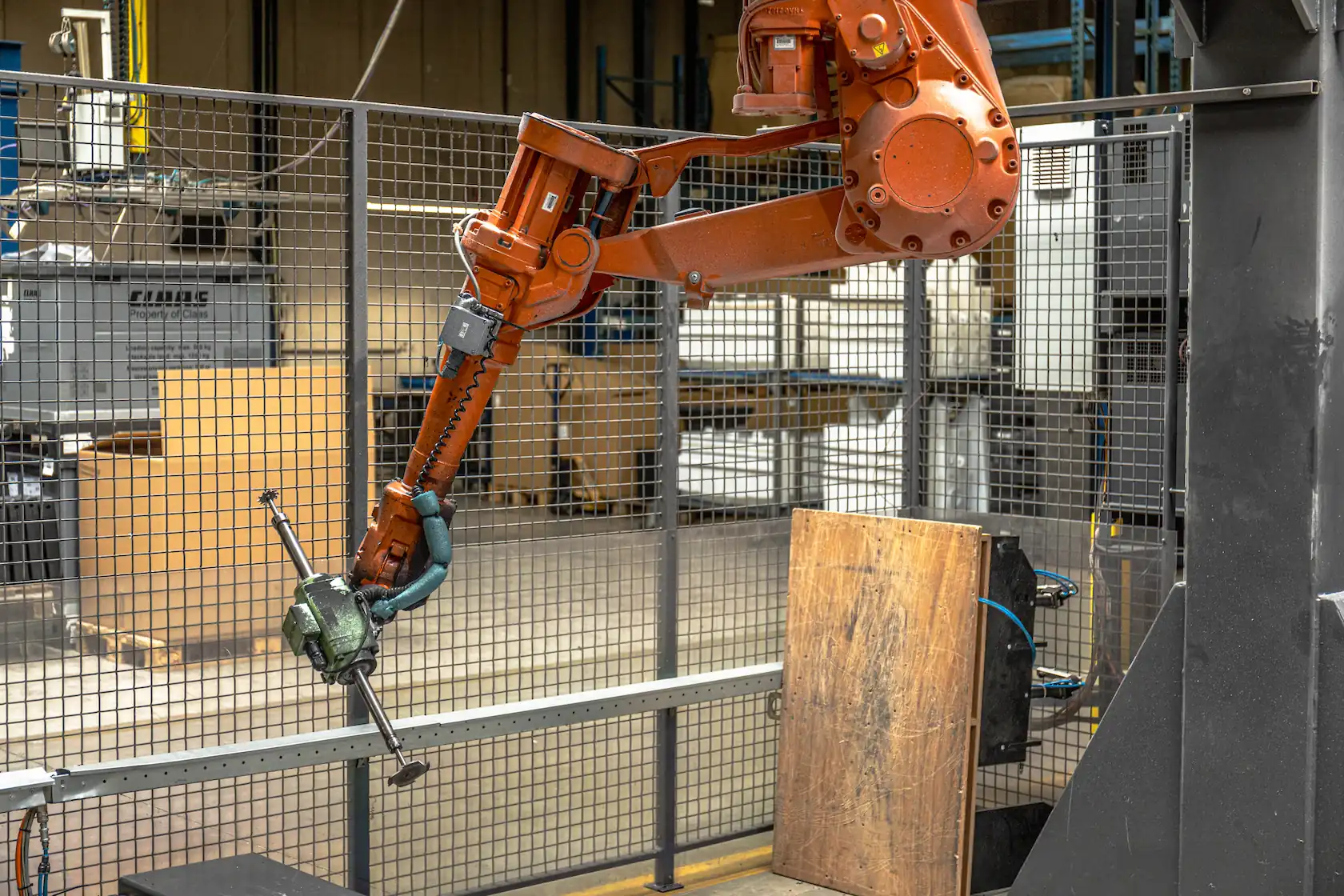

Robots for Efficiency and Consistency in the Production ProcessAt Pentas, automating processes has been ingrained in our DNA since our inception. We embrace this strength by deploying a series of specialized robots that support our production process and our colleagues. From accurately weighing and dosing raw materials to advanced robotic operations in the post-processing department, our robots play a crucial role in enhancing efficiency, consistency, and quality.

Quality

Comprehensive quality management and traceability at PentasThe importance of transparent and accurate information about every phase of our production process is increasingly significant due to recycling opportunities and quality control. From raw materials and assembly to final product properties and transport, every detail is meticulously recorded and traceable through our advanced Critical to Quality (CTQ) system.

Innovation

Innovation in knowledge retention: The role of augmented realityWithin the manufacturing industry, we face a crucial challenge: retaining our expertise. In collaboration with Saxion University of Applied Sciences, the University of Twente, and other partners, we are making a significant step forward by integrating augmented reality (AR) into our processes. This initiative aims to capture and transfer essential knowledge within our organization.